Rodwell Powell provides its customers with a service they can depend on. With a zero defect mentality, we ensure we stay at the forefront of quality.

From point of order, projects / components undergo advanced product quality planning (APQP) to ensure all possible escapes are not only brought to light but also prevented from ever reaching the customer.

Once parts are in production, Production Part Approval Processes or PPAP’s are used to determine total control over our machining methods before parts are eligible for production runs.

Process Failure Modes and Effects Analysis (PFMEAs) run in conjunction with the PPAPs to ensure we’ve captured the correct key Characteristics to determine how robust our control plans are.

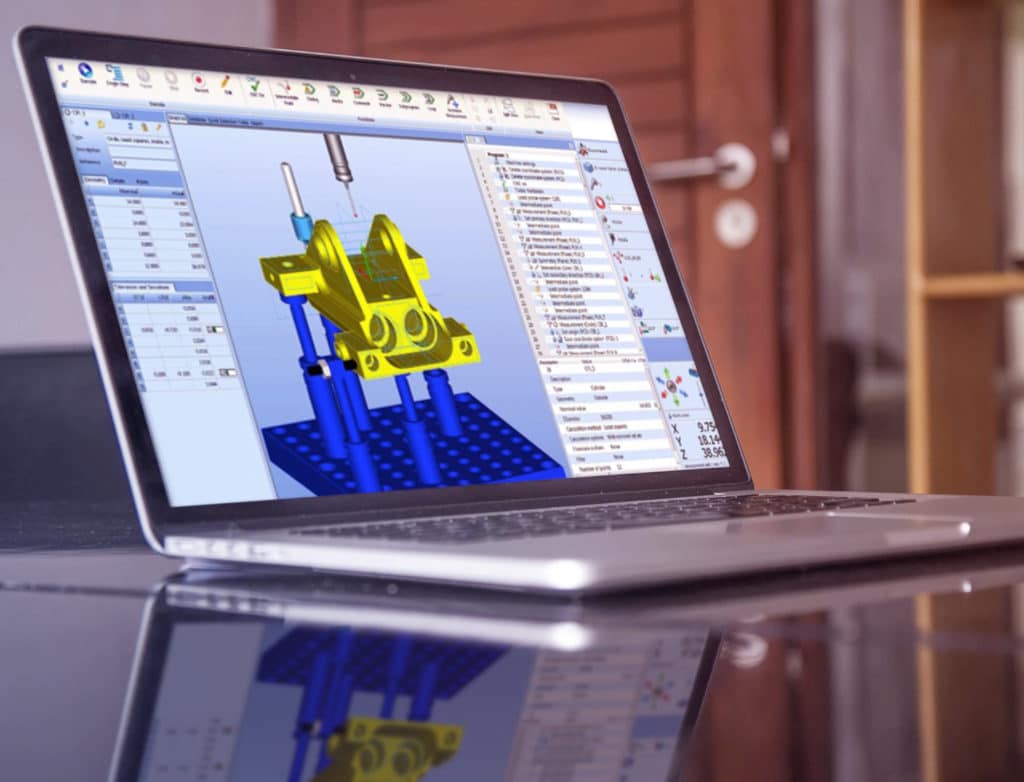

CMMs or more conventional measuring equipment that obtain the necessary Data, are all subjected to a gauge R&R (Repeatability & Reproducibility) process. This is to ensure that the measurement variation between Machinist and Inspection never exceed that of a controlled, reduced tolerance.

This is done via Mini Tab software, that clearly presents data over the entire batch while calculating any variants between those that are responsible for checking the parts.

At Rodwell Powell, we leave nothing to chance.

Approved contractors across a range of industries

- GKN Aerospace (USA)

- Doncasters

- Mecachrome (France)

- Rolls-Royce (UK)

- Rolls-Royce (Deutschland)

- Siemens (Canada, Sweden & UK)

- Ultra Electronics

- Caterpillar

- Enersys (Wales)

- INCORA

- M.O.D.

- Electric Assisted Vehicles Limited

- Kemet International

- Coborn Engineered Solutions

- Colins Aerospace

- Everrati Automotive

- MB Aerospace

- Perkins

- Radius Aerospace